Home | Photoalbum | Music | GameDev | RaspberryPi | Electronics

My projectsOXO - MIDI-drumbrain Rapit - RPI-robot LogiCal - 4bit calculator CNC - A work in prograss Bench power supply PiZoom - soldercam Piphone - smartphone |

CNC - Computer Numerical Control

This is my first CNC, build from two old optical drives and a small servo:

The second one I'm building, is a bit larger. And the plan is to have three switchable heads so it can draw, carve and print 3D objects. I have made a 3D model using Blender and uploaded a preview to my Youtube channel:

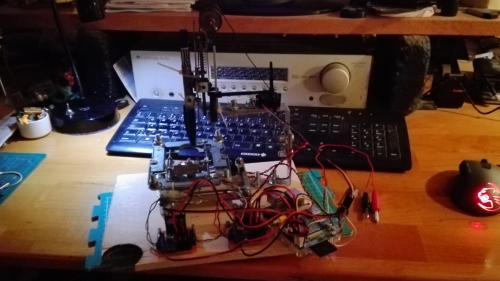

The final result is comming along slowly since I'm not used to work with metal and required some new tools for the job, but I have the first axis working as shown here (upside down):  As you might notice, there are a few deviations from the Blender model. It wassn't completely wasted time to make the Blender model first thou, it gave me an idea of what materials I was going to need and I was able to predict some of the workflow. X and Y axis hardware finaly working, and so far I quite pleased with the result:  And now for the fun part, wirring it all together and writing software :-) I use two stepper motors for X/Y and untill I get a third stepper, I'll just use a servo to control the Z axis. Almost done with my CNC. X and Y axis working with minor quirks, now I just need the last stepper motor to complete it. It's controlled by GRBL and Universal-G-Code-Sender running on Lubuntu. electronics:

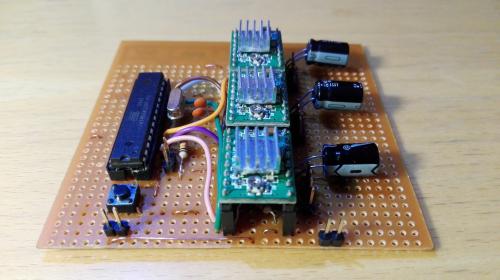

Ball bearings are a world in itself, but like many other things, they too can be found relatively cheap on ebay, I bought 10 4mm for about 6£ and 20 10mm for about 20£, but if you can also take them from an old skateboard or rollerskates. If you are comfortable using a soldering iron, you can build the A4988 drivers yourself, you can even build the Arduino yourself, but unless you have a spare decent 12V transformer laying around, the cheapest way to get a power-supply is to mod an old AT/ATX PC-PSU. I bought the A4988 drivers on ebay for £0.99 and it came with a heat-sink, so theres not a whole lot to save building it yourself, and it's the same thing with the Arduino. My PSU is build from an old ATX PC-PSU and I'll upload the procedure to my site one of these days. I made this neat little PCB on a matrix-board to hold the motor-controllers and the Atmega 328 circuit:  I also switched from using my old labtop to a Raspberry PI, that way all the electronics can fit in a nice box. |

Powered by penguins